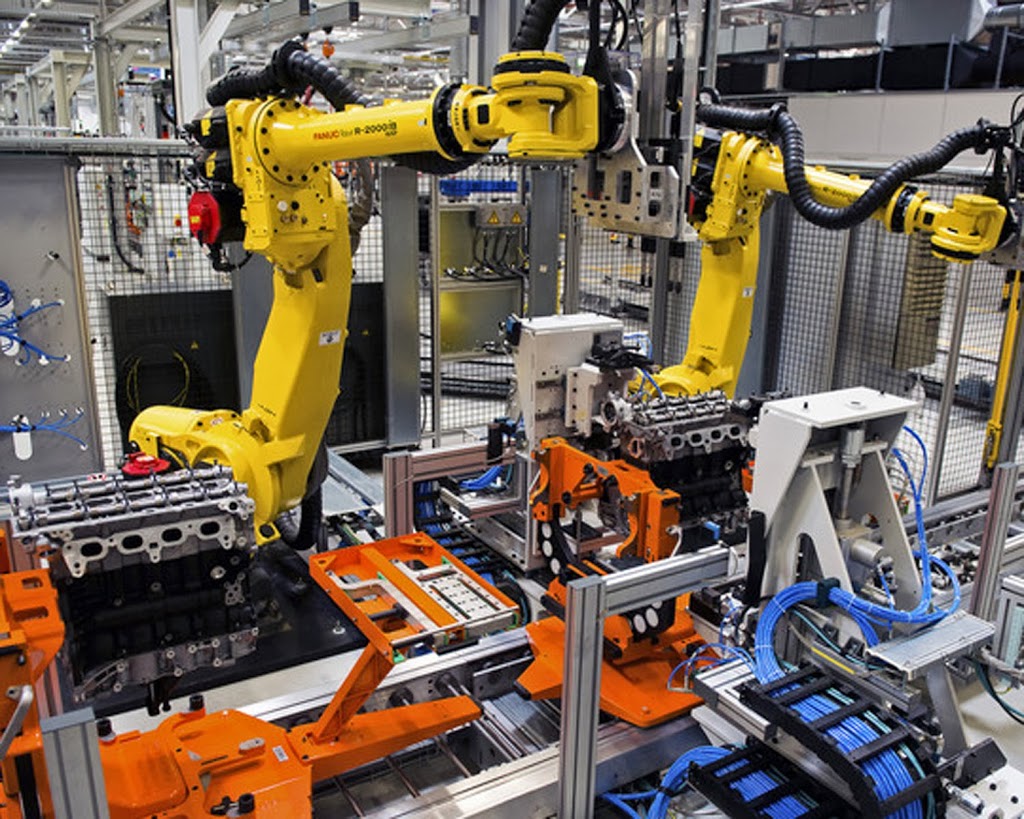

Industrial component supplier keeps manufacturing factories running

Manufacturing companies can’t afford downtime in their operations due to a purchased component being out of stock or worst discontinued. Extended periods of machine downtime that shut down the entire assembly line cost thousands of dollars per hour, that’s why it’s important to get purchased components from a reliable supplier that stocks product available for…