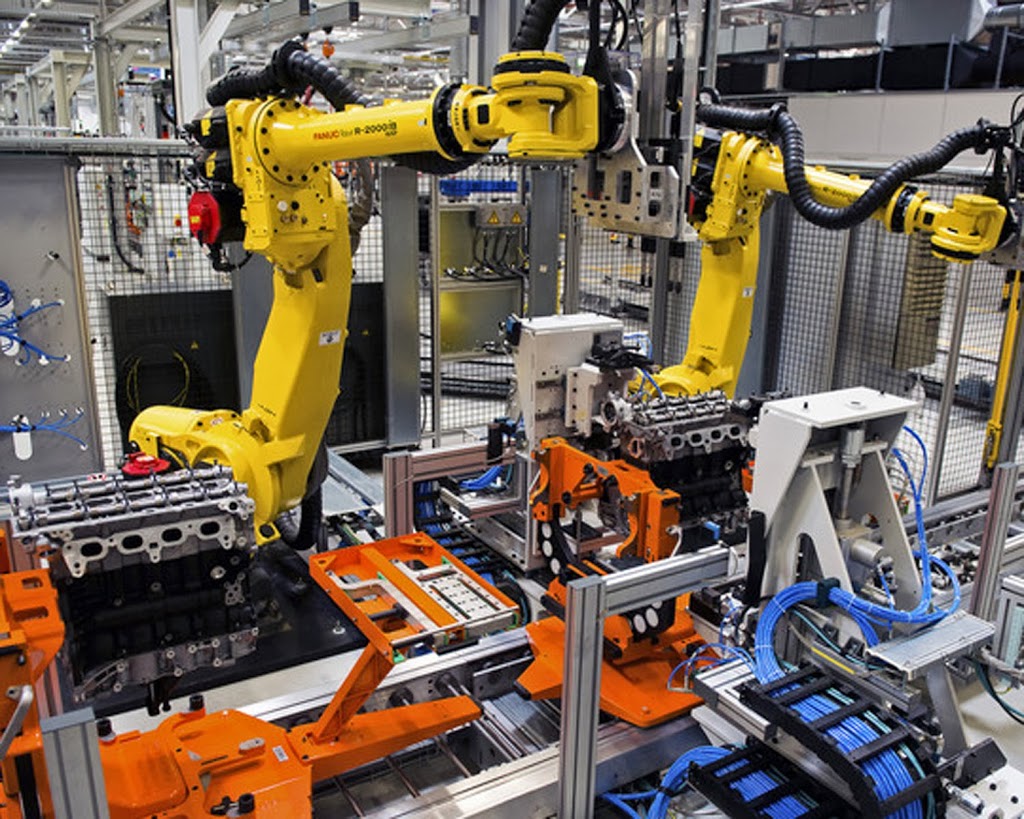

Robotic Tool Changers Improve Production & Safety on Factory Floors

Robotic Tool Changers improve production & safety.

The AGI robotic tool changer provides the flexibility to automatically change end-effectors or other peripheral tooling. The products are designed to function reliably for millions of cycles at rated load while maintaining extremely high repeatability.

Typically when robotic tool changers are required is when changing multiple end effectors, as part of improving production cycle in a given cell. A robot will use a pneumatic gripper to pick up and position a part, after that it exchanges the gripper for a grinder. When the grinder is complete, the robot drops off the tool and reattaches the gripper, so it can remove the piece from its fixture and pick up another part.

Another common application is where a robot uses a single end effector for a given product run, only changing out end effectors when the product changes. In some product lines are changing every couple of hours, so tool changers can both cut costs and increase throughput.

Robotic Tool Changer

Routine maintenance is another application in which tool changers help reduces the down time. The tool changer justifies its expense because end effectors can be swapped out in a matter of seconds, as opposed to hours so production can continue.

Safety is key in any factory environment. AGI’s Pneumatic Tool Changer are equipped with a fail safe locking mechanism that will not drop your part even if air pressure fails. The locking mechanism relies on a pneumatically driven piston that forces three cam fingers into a steel ring in the tool-side piece, both locking it in place and clamping the two pieces together. The cam geometry ensures the robot- and tool-side do not come apart in the event of lost air pressure.

The pneumatically actuated robotic tool changer provides the flexibility to automatically change grippers or other peripheral end-effector tooling. AGI offers seven different sizes of Tool-Changers, ranging from 1″ in diameter for lab use to 10″ in diameter. They can handle high load capacities up to 6000in-lbs and a repeatability of +0.01. Tool Changers (Robot side and Tool side) that have been designed to connect electrical contacts and pneumatic ports.

AGI supplies a complete range of sophisticated pneumatically actuated automation products that include, pneumatic parallel grippers, rotary actuators, thrusters, linear actuator slides, mini slides, tool changers, overload devices. Available in imperial and metric versions for flexibility of design for a world market. For more information on this product, send for a FREE catalog today. For immediate assistance, call AGI, at (203) 459-8345 or visit our web site at www.agi-automation.com .