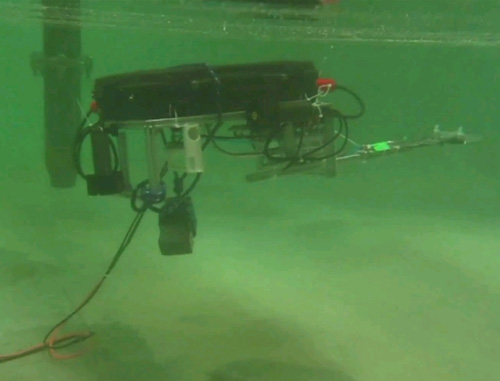

WSU Autonomous Underwater Vehicle equipped with robotic gripper

American Grippers Inc is proud to participate in sponsorship opportunities for University students majoring in Robotics and manufacturing. Washington State University Students are working on a self-operated robotic submarine to enter in the International RoboSub Competition in San Diego. The competition, in its 16th year, brings teams from around the world together to compete in a series of unmanned tests. The competition is hosted by the Association for Unmanned Vehicle Systems International and the US Office of Naval Research.

American Grippers Inc is proud to participate in sponsorship opportunities for University students majoring in Robotics and manufacturing. Washington State University Students are working on a self-operated robotic submarine to enter in the International RoboSub Competition in San Diego. The competition, in its 16th year, brings teams from around the world together to compete in a series of unmanned tests. The competition is hosted by the Association for Unmanned Vehicle Systems International and the US Office of Naval Research.

Washington State University entered the competition for the first time last year and was able to make it to the Semi-Finals. Their team placed 22nd out of the total 31 teams. Having been a first year team, this was a great accomplishment. Major integration of the software and hardware was undertaken just days before the competition and continued throughout the entire event. Last minute time changes also meant the pressure case had to be entirely rebuilt on-site at the event.

The software engineering component of the project focused the majority of their time on writing code for the control system, so that it was able to interact with the hardware of the submarine. They had full control of the depth and movement of the sub based on data input from all of the sensors. It was possible to shoot both torpedoes, drop both markers and actuate the robotic gripper. Another piece of software implemented last year was an image recognition program to detect all of the obstacles. In its current form the sub can accurately recognize the first six obstacles of the course, including the starting gate, the heading paths, the buoys, the obstacle course, the torpedo targets and the bins for the markers.

The group began planning earlier this year and recruited a mechanical engineering component to construct the waterproof shell for the robot. The computer science students continue to improve and enhance the code that will make the AUV’s operation autonomous. Finally, the electrical engineering students continue to focus on making the sub’s hardware more adaptable, robust, and power-efficient. In the coming year they will also be working on an acoustics system, enabling the AUV to locate itself with respect to an audible device underwater.

The WSU team looks forward to future competitions and hopes to continue to improve and develop the advancing field of underwater robotics. The WSU team looks forward to future competitions and hopes to continue to improve and develop the advancing field of underwater robotics. While in the development stage during the school year, the electrical engineering component created custom PCB’s which communicated commands to and from motor controllers, pneumatic valve banks, microcontrollers, depth sensors, gyroscope, accelerometer, and compass sensors. They were also required to design and construct many of the mechanical systems on the AUV, creating the pressure case and frame. By the end of the teams’ construction, the AUV was able to manually do almost every task in the competition.

The team’s major sponsors were Washington State College and Naval Sea Systems Command (NAVSEA). NAVSEA provided mentorship and donated $20,000 to the project. AGI Automation Components is among the sponsoring companies the team spotlighted. AGI makes pneumatic actuators and hardware for automated manipulation of objects and machines. AGI donated an incredible amount of time and hardware to the club. It was with these tools that it was possible for the AUV to interact with the outside environment. Without the generous donations of AGI, along with other supporters, the AUV would not have been able to grip, rotate, and pick and place objects, drop markers, or fire torpedoes.

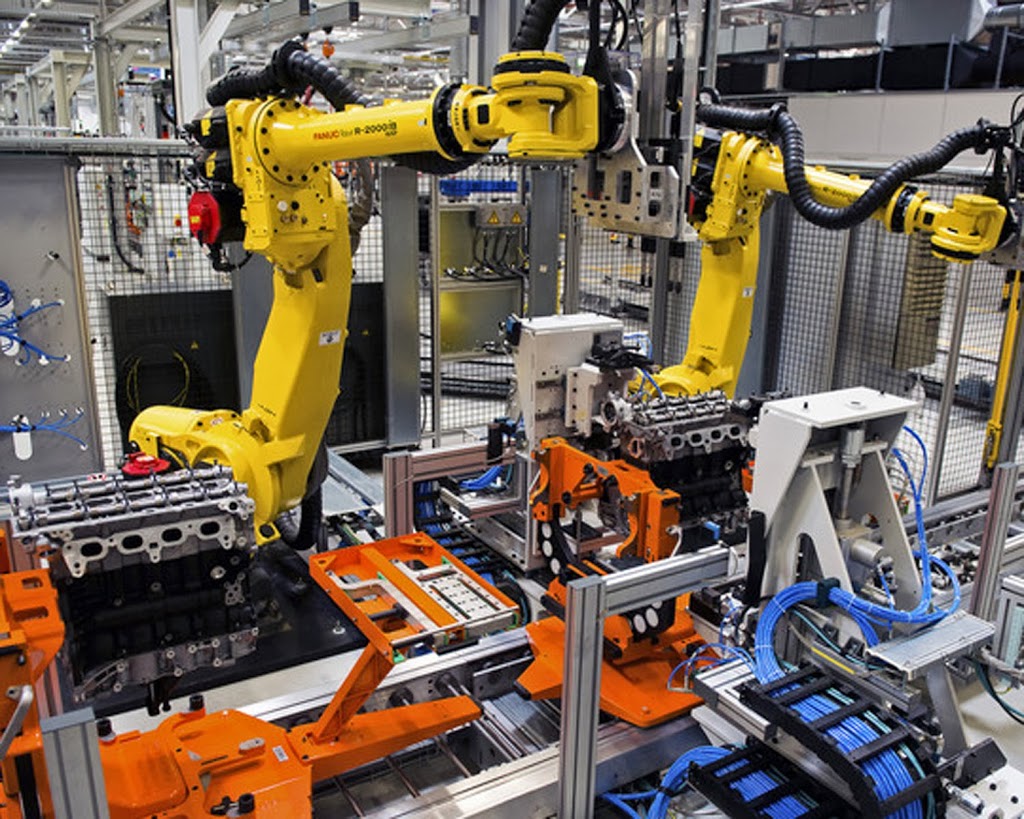

AGI manufactures Pneumatic Automation components like grippers, rotaries and linear actuators. Today’s sophisticated user of end-of-arm-tooling technology is confident in the capabilities and products of AGI, which are used for a variety of manufacturing processes including: Assembly, Pick and Place, Packaging, Loading & Unloading, and Part Transfer. For flexibility of design and accommodating use in the world-wide market, AGI products are available in imperial and metric versions. Manufacturing facilities the world over trust the automation components designed and manufactured by AGI American Grippers Inc.

In the upcoming competition the sub will be required to navigate an obstacle course with no direct or remote control. These obstacles include shooting torpedoes through targets, using sonar to locate an object, and navigating through gates. In addition to constructing their sub, the team is planning community outreach events to increase interest in artificial intelligence and robotics.