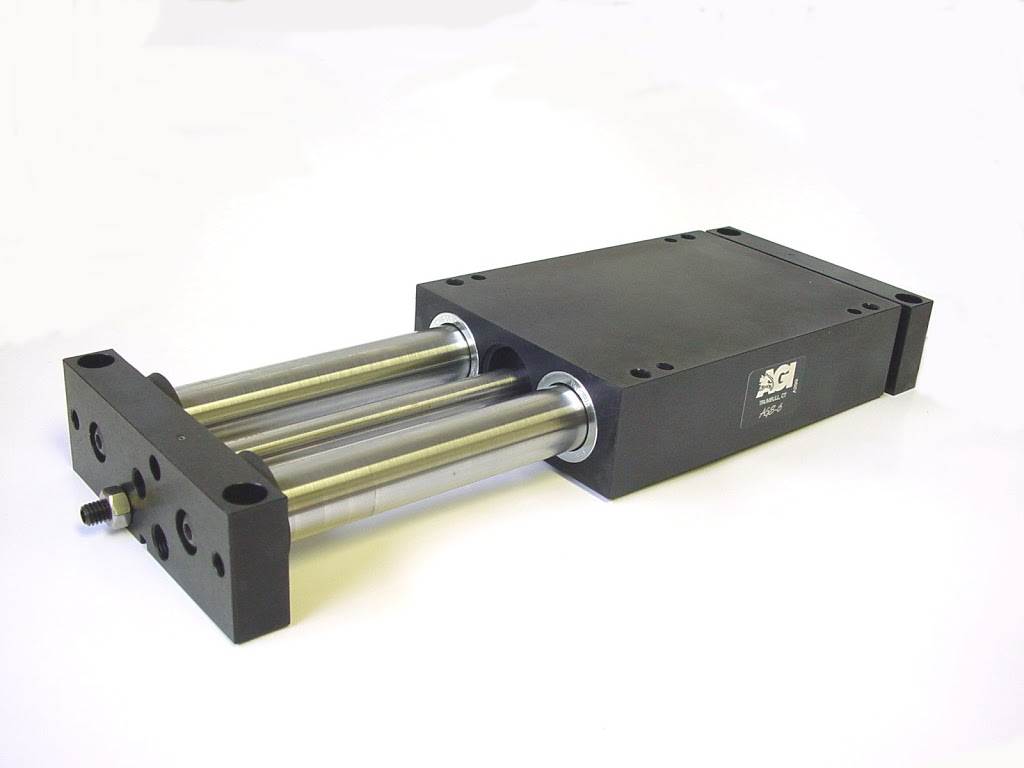

Precision Pneumatic Powered Linear Actuator Slides

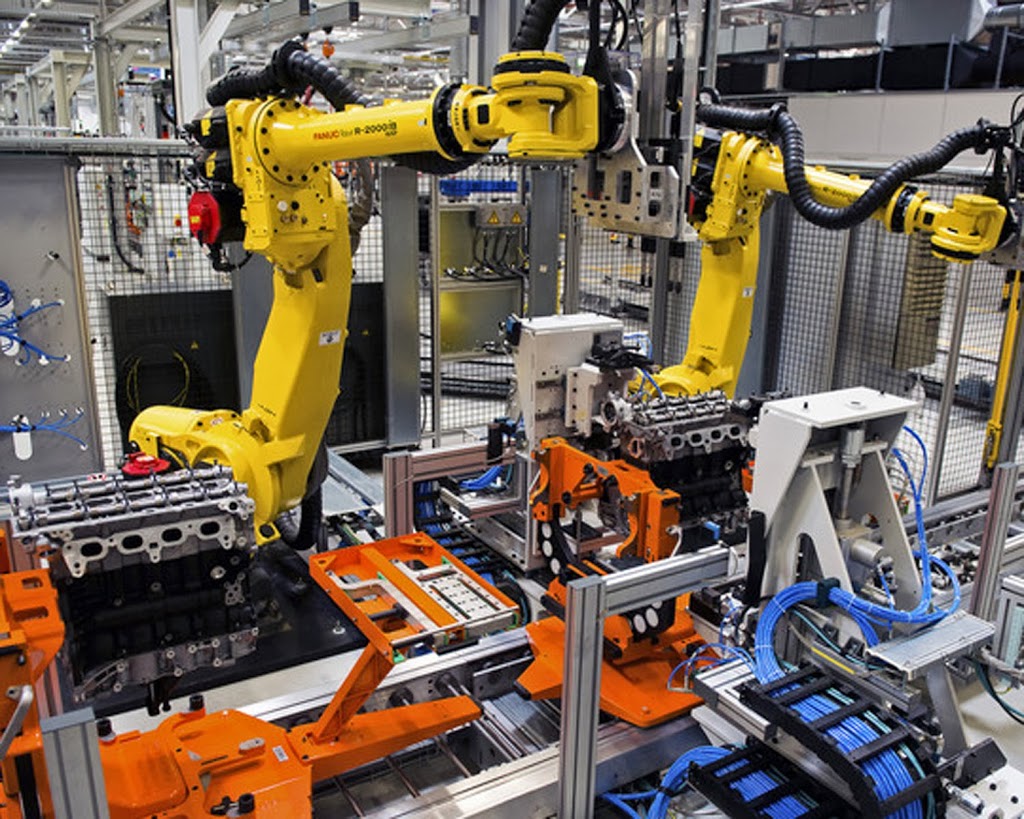

Pneumatic Powered Slide that provides smooth linear motion due to the precision ball bearings riding on hardened ground shafts. The aluminum body and end blocks contain tapped holes and dowel pin holes for precision mounting. AGS base slides have a built in air cylinder that reduces the overall length or footprint of the unit. Bore sizes are .75 inch, 1 inch and 1.25 inch with stokes from 1 inch to 6 inch. This linear actuator is heavy duty industrial grade, the end blocks are bolted to the shafts. The air feed shaft is gun drilled hardened shafting material to prevent air leaks and extending service life. Bearings are precision linear sealed type for heavy loading and polycarbonate composite bearings are also available. Pneumatic linear motion components are double acting air cylinders that require a four way two position valve. Flow controls (metering out) should be installed to regulate the speed of the device for smooth operation. Stroke adjustments are standard on both sides of the end blocks for fine end position adjustments. Optional shock absorbers and end position sensing can be added to slides, and are available in an inductive sensor that comes in both PNP or NPN sourcing.AGI has a full line of pneumatic linear actuators that are internally powered. The three styles are base slides, magnetically coupled rodless slides, thrusters and pneumatic actuators These pneumatic guided air cylinders are used in typical X-Y-Z motion Pick-N-Place applications and can handle small to medium size objects. Factory productivity improvements and cost reduction of repetitive task can be automated using base slides, thrusters and long stroke linear actuators in combination. www.agi-automation.com• Compact lightweight unit with built-in air cylinder.

- Linear ball bearings ride on precision hardened ground steel shafts.

- Units are permanently lubricated for non-lube air operation, allowing for OSHA compliance.

- Piston seals are U-cup type for long service life.

- Aluminum body and end blocks contain tapped holes and dowel pin holes for precision mounting or fixturing.

- Custom mounting holes and air ports can be added. Please consult factory.

- Main body or end blocks can be anchored due to the 1/16″ height clearance.

- Standard built-in stroke adjustment for precise, repetitive operation.

- Proximity switches are available to monitor end of stroke position of the body.

- Optional shock absorbers can be ordered for smooth operation.

- Series AGS-4 is fully field repairable for cost savings and minimum down time. Repair kits are available for repairs or maintenance.